Designing for wellness: Reinforced PVC membranes transforming luxury design

The growing consumer interest in health and wellness has significantly impacted the hospitality, tourism, and rehabilitation sectors. As luxury resorts and rehabilitation centres expand their wellness offerings, the demand for high-quality, durable, and esthetically pleasing aquatic facilities has surged. Reinforced polyvinyl chloride (PVC) membranes have emerged as a transformative solution, offering superior waterproofing, safety, and design flexibility. Their textured finish, designer colours, chemical resistance, and low maintenance make them ideal for swimming pools, spas, cold plunge pools, and therapy pools in wellness environments.

This surge in wellness demand aligns with the booming global wellness tourism market, valued at $639 billion in 2020 and projected to reach $1.1 trillion in 2025, growing at a 7.8 per cent compound annual growth rate (CAGR). International wellness tourism alone is expected to grow 10.6 per cent annually. Leading brands such as Six Senses and Aman are heavily investing in wellness resorts, responding to the 2019 Global Wellness Institute’s findings that 68 per cent of travellers prioritize wellness when selecting destinations.

To meet this growing demand, wellness resorts increasingly integrate aquatic facilities such as hydrotherapy pools, thermal circuits, and mineral baths. The 2019 SpaFinder Wellness 365 Report identifies hydrotherapy as a top wellness trend, with rising interest in thermal pools and aquatic fitness programs. Supporting this trend, a 2020 Business Insider report notes that more than 200 wellness hotel projects were under development globally. Rehabilitation centres also expand their services with aquatic therapy pools to aid injury recovery and promote wellness.

Consumer preferences are a key driver behind this expansion. A 2018 Wellness Tourism Association report found that 40 per cent of travellers value wellness features, while a 2021 Tripadvisor survey shows nearly 70 per cent seek more wellness experiences. This growing demand underscores the need for hotels, resorts, and rehabilitation centres to expand their aquatic wellness offerings.

To effectively meet these evolving expectations, integrating aquatic wellness features with reinforced PVC membranes enhances guest satisfaction and ensures long-term durability and safety. Over the past five years, especially in Europe, a shift has been toward using reinforced PVC membranes to make wellness and rehabilitation pools watertight. Architects, designers, and installers prefer these membranes for their soft, textured finish, attractive designer colours, chemical resistance, and ease of maintenance across all temperatures. Additionally, many PVC membranes are class C slip-resistant, ideal for wet areas such as locker rooms and hallways where patrons walk barefoot.

Hot tub/spa wellness soaking

Reinforced PVC membranes are most commonly used for pool interiors, but they are also ideal for hot water soaking applications and spas with hydrotherapy pools featuring jets. Similar to its effects on other materials, chlorine becomes more aggressive at elevated temperatures. The focus is not solely on the material’s benefits but on its ability to endure harsher water conditions. To ensure durability, PVC membranes undergo rigorous testing, passing a 20-year life-cycle laboratory assessment with chlorine at pH 7 and a temperature of 40 C (104 F). For instance, The Grand Bohemia Hotel in Prague, Czech Republic, boasts an elaborate wellness centre with a spa basin, adjacent walls, and showers entirely lined with PVC membrane.

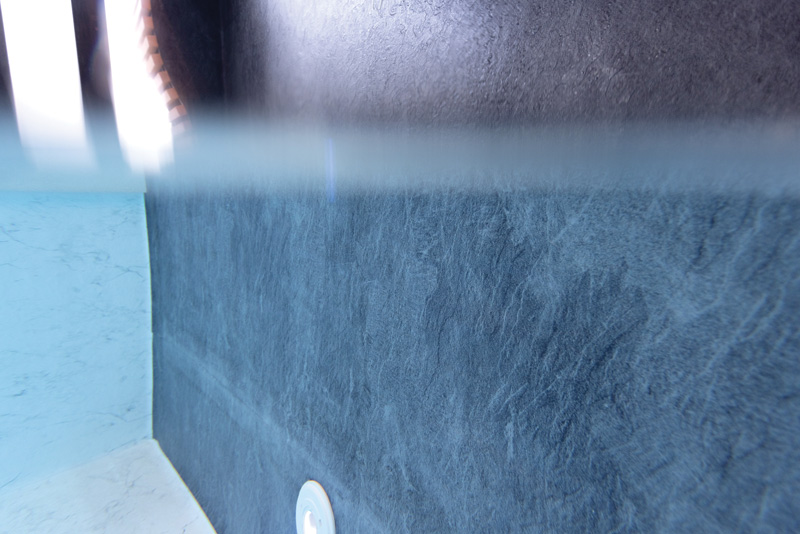

In the Canary Islands, Gleomar Piscinas, a builder, opted for a PVC membrane that provided rich colours and textures, resulting in a unique esthetic that complemented the surrounding hotel’s architectural style. The hot tub and spa basin were lined with a light-coloured membrane that mimics the appearance of marble, while the adjacent showers and walls were finished with a dark PVC that resembles slate. The client was highly satisfied with the outcome and appreciated the product’s watertightness guarantee.

The recommended water temperature for maintaining the colour stability of PVC membranes is 32 C (90 F), a standard determined by the interaction between chlorine and temperature—recognized as the primary factor affecting colour retention. Specific precautions are advised for installations operating at higher temperatures to preserve the membrane’s integrity. The membrane should be installed under maximum tension on both walls and floors to prevent any potential movement, with contact cement on all wall surfaces for extra security. Opting for a thicker membrane, such as an 80 mil product, is also recommended instead of the standard 60 mil version to enhance durability. Further, end-users must be properly instructed to carefully monitor chlorine concentration levels, as chlorine becomes more aggressive and corrosive at elevated temperatures, potentially damaging the protective coating of the membrane.

Rehabilitation pools

Many rehabilitation and therapeutic spas are now lined in PVC membrane not only because of their beauty, watertightness, and ease of installation but also because the material is soft on users’ feet. One example is the rehabilitation pool located in Padua, Italy, at a physiotherapy medical centre, lined with reinforced PVC membrane installed by Klant, a local designer and builder of pools. The facility is dedicated to neuromotor, speech therapy, and psychological rehabilitation treatment for outpatients suffering from neurovascular, traumatic, and postoperative orthopedic procedures. In the case of this therapy pool, a PVC membrane offers the look and feel of a golden sand surface that is soft to the touch.

PVC membranes have physical characteristics that can positively contribute to the safety and sustainability of these rehabilitation environments. Notably, PVC’s non-porous surface can reduce up to 90 per cent of surface bacteria, enhancing hygiene. Since individuals with specific health conditions frequently use rehabilitation pools, the waterproof properties of PVC membranes are essential in preventing issues such as mould, mildew, and water infiltration into surrounding structures. This supports stricter sanitation standards, which are vital in clinical settings. Additionally, PVC membranes offer several other benefits, including durability and longevity, effective waterproofing, flexibility for easy installation, and overall cost-effectiveness in building costs and maintenance.

The slip-resistant properties of this textured membrane make it safe for swimmers, especially those in recovery. It meets Class C slip resistance standards, the highest rating for wet areas, and is certified under several key safety standards. The EN 16165:2022 standard, widely used across Europe, tests the slip resistance of flooring surfaces to ensure safety in both wet and dry conditions. Additionally, the membrane complies with EN 13893, a European standard that measures dynamic slip resistance in dry environments, making it suitable for indoor public and commercial spaces. It also meets the ANSI A326.3–Dynamic Coefficient of Friction (DCOF) standard, a North American guideline that assesses slip resistance in wet conditions, ensuring safety compliance in facilities throughout Canada and the U.S.

Myrtha Pools, an Italian pool contractor, partners with the author’s firm to use its high-quality PVC membrane in the growing market of rehabilitation pools and wellness spas. The company’s reinforced slip-resistant PVC membranes are applied to all pool floors and stair surfaces to ensure maximum safety. Myrtha designs and builds pools specifically tailored to meet clients’ therapy and rehabilitation needs, including aquatic rehabilitation pools that enable weightless exercises for joints, ankles, knees, and the back. This near-weightless environment is especially effective for recovery following lower limb surgeries.

Lacquer’s role in extending PVC membrane lifespan

UV protection and weather resistance

The protective lacquer on PVC membranes significantly enhances their durability by offering strong UV resistance and weather protection. UV-resistant additives in the lacquer shield the membrane from UV radiation, preventing the degradation of the polymer structure, which could lead to brittleness and loss of flexibility. Additionally, the coating protects against harsh weather conditions, such as extreme heat, freezing temperatures, and heavy rainfall, reducing the risk of cracking or becoming brittle over time. This dual protection extends the membrane’s service life in challenging environments.

Chemical and abrasion resistance

PVC membranes that are fortified with a protective lacquer offer exceptional chemical and physical abrasion resistance. The chemical-resistant barrier prevents damage from exposure to cleaning agents, oils, and other harsh substances, minimizing the risk of degradation or discolouration. Moreover, the lacquer improves abrasion resistance, safeguarding the membrane from wear and tear due to physical contact, making it ideal for high-traffic or rugged environments.

Moisture and stain resistance

The lacquer applied to PVC membranes enhances their natural waterproof qualities by adding an extra hydrophobic layer. This additional protection prevents moisture absorption from both sides, which is crucial for preventing mould growth and structural weakening in wet environments like pools. Further, the lacquer serves as a stain-resistant shield, stopping dirt, algae, and organic materials from adhering to the surface, thereby preserving the membrane’s appearance and performance.

Enhanced flexibility and tensile strength

The protective lacquer also improves the membrane’s flexibility and tensile strength, making it more resilient under mechanical stress. This flexibility helps prevent cracking or breaking during expansion and contraction caused by temperature changes, particularly important for structures like elevated pools. The lacquer further reinforces the membrane’s durability, enabling it to withstand external stressors such as wind, vibration, and minor impacts, thus preventing tears and punctures.

Esthetic preservation

The protective lacquer preserves the colour and surface quality of PVC membranes to maintain visual appeal. It prevents fading and discolouration caused by prolonged exposure to sunlight and weather, ensuring the material remains vibrant in visible applications. Additionally, the lacquer resists dirt buildup, algae growth, and staining, maintaining a clean and smooth surface. This enhances esthetic appeal and promotes hygiene and safety in environments like pools where cleanliness is critical.

Increased performance in high-risk environments

In high-risk environments, the protective lacquer boosts the membrane’s resilience against harsh conditions. It offers resistance to saltwater and chlorine, which is essential for maintaining integrity in chlorinated or saltwater pool settings. The lacquer also protects against heat-related degradation, ensuring the membrane retains flexibility and strength even in high-temperature areas like roofs or hot climates. This comprehensive protection ensures long-term performance and durability in demanding applications.

Hotels, resorts, and luxury living pools and spas

Hotels and luxury resorts often feature elevated pools and spas that must be completely watertight. To ensure this, builders use weld-in-place PVC membranes, which have proven effective in maintaining watertightness. These membranes have been utilized in high-profile projects like the Porsche Design Tower and numerous other luxury towers in Miami, Fla., where private hot tubs are installed on balconies, sometimes up to 50 stories high. Builders and designers opt for PVC membranes for their reliability in these critical, high-end installations.

It is essential to recognize that reinforced PVC membranes fully seal the pool structure, ensuring it remains watertight. This makes them suitable for both renovating existing pools and constructing new ones. Importantly, these membranes are resistant to deterioration from acidic water conditions. Further, the commercial-grade reinforced PVC membranes are coated with a protective lacquer that enhances their durability against tears, chemical exposure, water absorption, and UV damage.

Weld-in-place PVC membrane interiors are perfect for custom pools, as they are installed on-site, accommodating even the most challenging shapes. This capability enables builders to achieve an exact fit. The reinforced PVC comes in 60, 70, and 80 mil thicknesses, enhancing its durability.

Once the PVC membranes are installed, the underlying surface can continue to shift and crack without affecting the membrane’s integrity. These installations often come with a 20-year warranty on the material, making them ideal for high-end applications, such as luxury destination hotels and resorts with wellness centres.

Weld-in-place PVC membranes provide pool finishes with unique advantages that other systems (e.g. marbelite, stone-coloured quartz finishes, or thermoplastic coatings) cannot offer. A key benefit is that the membrane does not crack under freeze-thaw conditions or due to ground movement. The membrane fully seals the pool structure, ensuring it remains watertight. This makes it an excellent choice for new construction and renovating pools and spas, particularly for elevated designs.

The perfect combo of strength and waterproofing

The modern designer-reinforced PVC membrane waterproofing system is rapidly gaining popularity among pool builders, architects, and specifiers. This system combines strength and waterproofing, making it an ideal choice for constructing wellness and rehabilitation pools and spas.

In addition, there are decking solutions that feature a reinforced PVC membrane designed explicitly for water-prone environments, both indoors and outdoors. This membrane is primarily used for decks surrounding pools, spas, and hot tubs, as well as in locker rooms, shower areas, and splash pads.

This material is suitable for new construction projects and renovations of existing decks, as it can be easily installed over most deck and floor surfaces, especially cracked, worn, or in disrepair. This makes it a perfect watertight solution. The slip-resistant textured surface provides superior comfort for bare feet, offering a more pleasant experience than concrete or wood, which can become uncomfortably hot or slippery when wet.

Additionally, this PVC membrane has a protective acrylic coating similar to that found on swimming pool liners, making it resistant to stains, chlorine, and UV degradation.

Author

Tony Jordan has more than 35 years of experience in the manufacturing, sales, and application of polyvinyl chloride (PVC) reinforced pool membranes for commercial and residential use. He is the business development manager at RENOLIT and can be reached at tony.jordan@renolit.com. For more information, visit www.renolit-alkorplan.com.