ORP and pH control: A service pro’s advantage

Swimming pool oxidation-reduction potential (ORP)/pH controllers have been around since the mid-1970s, but were very large and expensive, so they were typically found only in municipalities. The greatest innovations came in the early 1990s, when controllers became powered by microprocessors instead of analog technology.

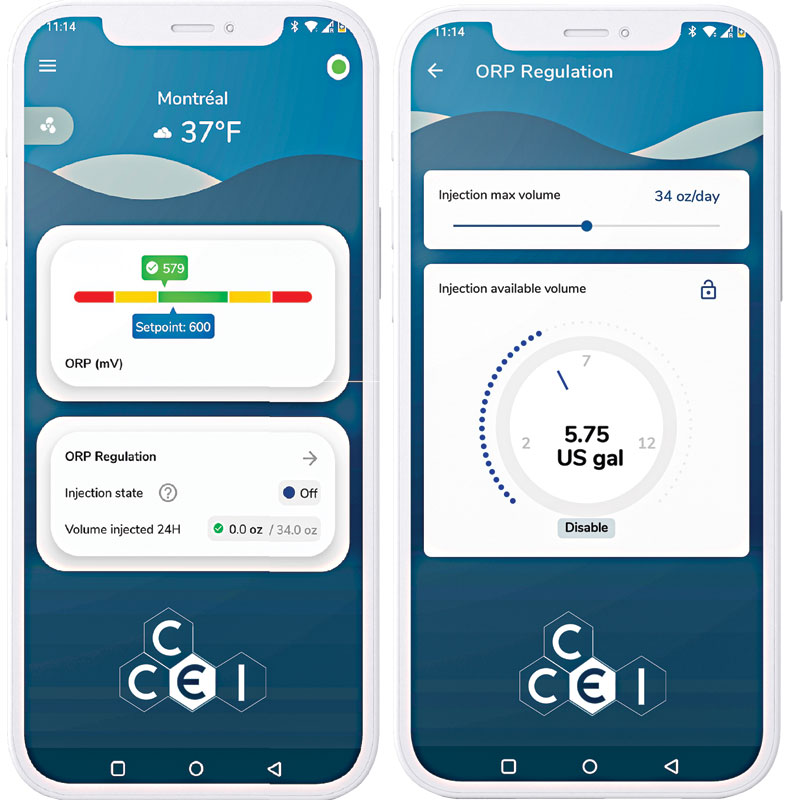

Simple automation systems with ORP and pH controllers have come a long way. They are now smaller, simpler, and easily connected with apps—allowing customers to ensure their swimming pool water chemistry remains in balance to prevent issues with sanitation or damage to pool equipment or even the pool’s construction. However, it is important that pool professionals have a clear understanding of what ORP and pH measure. Being able to provide a simple explanation to clients is important when selling these units, as well as explaining how to understand the measurement levels when consumers are operating and reviewing the measurements on their connected phone app.

Understanding oxidation-reduction potential (ORP)

ORP measures the oxidizing properties of any sanitizer present in the body of water. Most controllers use a bypass system that takes a small sample of water out of the plumbing and directs it into a small container that houses the sensors. When the chlorine is actually able to oxidize, the sensors generate a millivolt reading, which is expressed as an ORP measurement. If the chlorine is not free and available, the millivolt reading will not be generated.

ORP is a qualitative measurement which is constantly changing in outdoor pools primarily due to varying CYA levels and sunlight intensity. It is important to remember and explain to clients that the ORP measurement changes throughout the day because it is affected by factors such as pH, cyanuric acid, combined chlorine, and salt-chlorine generators. Essentially, ORP is a moving target, so having a simple system that reports or shows the safe “range” of ORP is important. Simpler ORP controllers will show the results as green (good), orange (moving out of range), and red (out of range) to make it easy to interpret.

It is important to remember that the “P” in ORP stands for potential. ORP provides a measurement of the chlorine’s potential ability to oxidize and, therefore, sanitize at a particular moment in time. ORP is not an actual measurement of sanitizer; rather, it is a measurement of the chlorine’s ability to oxidize. Chlorine is constantly being chemically tied up with factors such as phosphates, high-bather loads and pH fluctuation. Therefore, most controllers and feeders measure ORP and pH in a body of water and dose accordingly.

ORP measures the water’s ability to oxidize and depends on pH when the primary sanitizer is chlorine. This is one of the reasons that pools should be equipped with both an ORP and a pH controller/ feeder. Cyanuric acid levels can affect the readings taken by an ORP sensor, and even sunlight affects ORP readings. If observed closely, there tends to be a distinct pattern of rising and falling of ORP at both dawn and dusk on outdoor pools. The ORP will always go up at dusk, as the sun goes down, because lower UV levels degrade the chlorine, so the chlorine no longer needs to combine with cyanuric acid to protect itself from the UV coming from the sun. Chlorine is more available when no longer exposed to UV; therefore, it has a greater potential to oxidize because it is not tied up with cyanuric acid.

Conversely, the ORP readings go down at dawn or as the sun rises and the UV rays start hitting the pool water, causing the chlorine to combine with cyanuric acid to protect the chlorine, but at that time, the chlorine is less “free,” meaning it has a lower oxidation potential at that moment in time. This does not mean the chlorine cannot do its job, because it will break free as needed to oxidize and sanitize. The ORP measurement is valuable in that it signals pool owners and pool professionals about what factors might inhibit the chlorine’s ability to oxidize.

Is it the high bather load that has introduced high levels of organics, such as sunscreen? Perhaps the chlorine is tied up with phosphates introduced from the source water? Or is it the sudden introduction of large amounts of pollen?

Automation benefits

Using ORP controllers is the most cost-effective solution to measure sanitizer levels. ORP helps identify how the sanitizer in the water is working and helps determine the factors that might be making the sanitizer less effective at keeping the pool water clean. By understanding how these readings are generated and the factors that affect the readings, service techs and pool owners can better adjust their water chemistry using an automation system with an app on their phone.

Using the latest automation technology with convenient smartphone apps allows pool technicians and owners to monitor and dose pool water to obtain the cleanest, clearest water for swimmers, save chemicals, and help protect pool equipment and surfaces.

Pool professionals agree that automation systems can help avoid problems that increase a pool’s operating costs. While automation does not replace regular service, systems such as chemical controllers and feeders ensure all systems function correctly between service calls.

Service professionals can enhance the service they provide. By having more access to real-time equipment status and remote access, they can get information ahead of time so they can make their service calls more efficient and effective. In addition, with monitoring services, service professionals can provide customers with a higher level of personalized, premium service that goes beyond standard expectations—offering upselling opportunities and building strong customer relations.

Automation systems provide valuable data, enabling pool service professionals to identify issues, such as pH imbalances, before they escalate. This proactive approach gives pool professionals a competitive advantage by allowing for more specific discussions with clients rather than general inquiries about backyard conditions.

Offering simple ORP/pH automation systems

Pool automation, including ORP/pH systems, helps boost customer satisfaction and excitement about their pool. These systems simplify pool maintenance and make operating other components easier, even remotely with phone apps. Automation enhances the backyard experience, providing everything from optimal water temperature to chemically balanced and sanitized water chemistry.

Understanding how these controller systems function and explaining what the controllers measure is an integral part of empowering customers with the new apps they will be downloading to their smartphones.

Offering and installing simple automation systems helps modernize pools for customers while differentiating a business from competitors. Simple automation systems with ORP and pH controllers are now smaller, simpler, and easily connected with apps—making them a game-changer for pool and spa professionals. In addition to upgrading pools, automation fosters customer loyalty by empowering clients with greater control and enhancing their sense of ownership over a more modern pool experience.

Author

Martin Grenier is the Canadian commercial sales manager for CCEI, a manufacturer of automation and controller systems in the United States and lighting systems in Canada, Mexico, Europe, and Africa. The company’s head office is located in France. Grenier has more than 10 years of experience in the swimming pool industry, having worked for Hayward for over seven years and held other positions in retail and distribution. He can be reached at mgrenier@ccei-pool.com.