Identifying pool heater problems: Why installation mistakes lead to failures

Identifying and resolving pool heater malfunctions was the initial step that led the author’s company into the aquatic industry. Originally specializing in commercial and residential hydronic heating, the business focused on boilers and water heaters as its core expertise. While services in that sector continue, the company’s capabilities have expanded.

Fifteen years ago, the idea of designing, installing, and troubleshooting pool heating systems for homeowners and some of the largest waterparks in the mid-Atlantic would have seemed improbable. However, the principles of thermodynamics remain constant, regardless of the application.

The company’s entry into the aquatic industry began when a local YMCA reached out after finding its name listed as an authorized service provider for the heating appliance serving their indoor pool. The unit in question was a volume water heater capable of functioning as both a boiler and a pool heater—an area where the company already had extensive experience. The facility had been replacing the heat exchanger on its old heater annually, and despite installing a new unit, the system required a new burner tray after only eight months. After diagnosing and correcting the issues, the unit remains fully operational nearly a decade later.

It all starts with proper installation

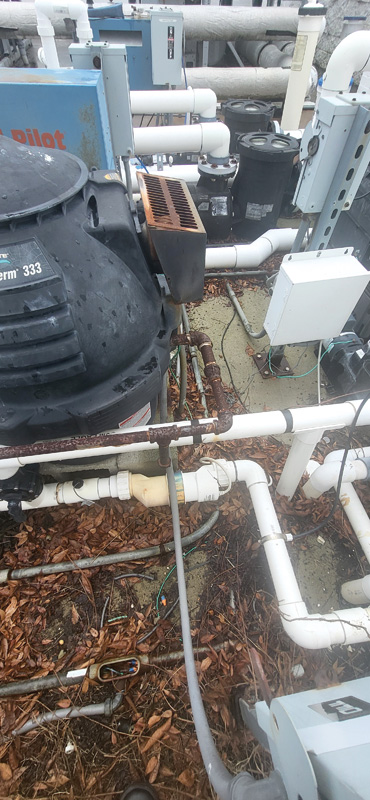

More than 90 per cent of pool heater failures the company encounters result from a safety device responding to an installation issue. These problems often originate during system design and continue to compound over time. When troubleshooting a heater, it is essential never to assume it was installed correctly—more often than not, it was not.

A common installation mistake is failing to read and follow the manufacturer’s manual. Manufacturers provide detailed installation guidelines for a reason—they are essential for ensuring proper setup and preventing issues down the line. The three most common causes of failure include improper gas supply, water flow issues, and venting mistakes.

Gas supply

One of the most frequent problems the company encounters is an undersized gas line or improperly regulated gas pressure. For example, a 750,000 BTUh pool heater may have a 25.4-mm (1-in.) gas stub-out, but that does not mean the entire supply line can be 25.4 mm (1 in.) in diameter. While a 25.4-mm (1-in.) pipe may be sufficient for the final 457.2 mm (18 in.) within the appliance cabinet, it is inadequate for the entire gas supply line.

The correct pipe size depends on the developed length of the pipe from the meter and the appliance’s firing capacity. Guidelines are supplied in the manual.

Some installers assume that the job is done once the appliance fires up. However, pool heaters must be commissioned following the manufacturer’s start-up procedures, including checking manifold and static and dynamic gas pressure. High-efficiency condensing units typically require even more detailed commissioning.

Venting

Improper venting (exhaust piping) is another leading cause of heater failures, particularly in indoor installations. Venting issues are doubly critical because they pose a risk of damage or downtime and a threat to the health of building occupants.

It is extremely important to follow the manual and local codes exactly. Improper venting material, vent sizing, and vent lengths will cause problems that are both expensive and dangerous. Flue gas leakage inside a building is a severe, life-threatening issue.

Hydraulics

Improperly installed or obstructed pool water piping is another likely culprit when a pool heater goes down. Lack of flow can cause the appliance to shut off or damage the heat exchanger and system pumps.

A common mistake is misunderstanding developed length versus linear distance. For instance, if the manual states that the filtration loop must be within 4.57 m (15 ft) of the unit, that includes every bend and fitting, not just straight pipe length. An elbow, for example, might equate to 1.52 m (5 ft) of developed pipe length. It is all about the head (or resistance to pumping).

Regardless of the reason, if the pump cannot overcome the resistance of the attached piping system at a given flow rate, the volume of water moving through the heat exchanger will be lower than intended. Insufficient flow through the heat exchanger can cause damage, or the appliance may shut off. Lack of flow is a real concern.

Water quality

Water chemistry can be a major issue for bathers and mechanical components alike. If the pH is allowed to fall too low, it can deteriorate the appliance heat exchanger. Water quality concerns can result from negligence or improper installation.

For example, spikes in treatment chemical concentration can occur if the installer fails to place a check valve between the heater and the chemical injection points. These chemicals can get into the heat exchanger and remain there for a long time. Most treatment chemicals are very corrosive in high concentrations.

High levels of calcium or other dissolved solids can lead to another set of concerns. When exposed to high temperatures, dissolved solids come out of solution and adhere to nearby surfaces, often called scale. This frequently causes buildups and blockages within the heat exchanger. Early on, this causes a drop in thermal efficiency, but as it develops further, it negatively impacts the flow rate through the heat exchanger and can cause major failures.

Troubleshooting and maintenance best practices

The company is often called to troubleshoot pool heaters not installed by its team. Of those, more than 80 per cent receive a red tag, indicating an issue that cannot be overlooked from a liability standpoint.

Whenever the company installs a heater, a start-up form is completed—a practice now required by most manufacturers for warranty validation, particularly for commercial units. Documenting maintenance and troubleshooting is equally important. When diagnosing an issue, it is essential to continue investigating even after identifying one problem, as multiple issues often exist simultaneously.

Before leaving the office, the team downloads and prints the installation and operation manual specific to the heater’s model and serial number. This is followed by a process referred to as the “flashlight and highlighter” evaluation. While reviewing the manual, the entire heating appliance, along with its connected gas piping, venting, and primary filtration loop, is inspected. Any discovered issues are highlighted in the manual, and the evaluation continues. Discrepancies between the manual and the installation are then systematically addressed.

Proper maintenance

Maintaining a pool heater is much like maintaining a car. A vehicle would not be driven year after year without an oil change or tire replacement, and the same principle applies to these appliances. Pool heaters should be routinely inspected and maintained by a professional who performs a full evaluation, cleans the unit according to manufacturer guidelines, and completes recommissioning by checking gas pressures, flow rates, and other critical parameters.

The company’s approach to system protection includes offering long-term maintenance agreements and extended warranties. When clients invest in a heating system from the company, they are also investing in ongoing service and warranty protection, ensuring reliable performance and longevity.

Manufacturers design heaters to last, not to fail. Proper installation and maintenance depend on installers and service professionals reading and following the manual.

Author

Tom Soukup is the principal of Patriot Water Works Co., and he has more than 20 years of experience as a hydronic designer and installer. He specializes in high-efficiency and green technology and brings his expertise to custom hydronic work, pool heating, and agricultural projects. He can be reached at twsoukup@patriotwaterworks.com.