Pool resurfacing

What are micro-glass coatings?

It is a more complex material than standard paints used in the pool industry. These coatings are a high-performance, high-build, corrosion-resistant, glass fibre-reinforced polymer spray-applied to steel and concrete. Plural component spray equipment is used. The hose length is 61 m (200 ft) and eliminates hot potting. For efficiency, 208 L (55 gal) drums are used and remain on a trailer during spraying operations. The spraying of coatings can yield superior results to other coating applications. All complex polymer coatings are spray-applied.

Benefits of glass flake in coatings include:

• improved thermal stabilization and mechanical properties of the coating;

• reduced gas and moisture permeation;

• extended coating life and consequently a long service life;

• less cracking and peeling;

• increased hardness, wear, chemical and abrasion-resistance;

• low ife-cycle cost without periodic refinishing; and

• superior moisture vapour transmission (MVT).

Preparation

Preparation depends on the type of pool. Fibreglass pools require light abrasion, before spraying. The application rate is fast at 93 m2 (1000 sf) in under 60 minutes. That said, it is important for applicators to repair any suspect areas first.

Marbelite pools must be acid etched for bond promotion—chipping out of old plaster is not required; however, masking off the deck and fittings is important. Steel pools must be abrasive blasted for an angular 0.13 mm (5 mil) profile, then primed to avoid flash rust.

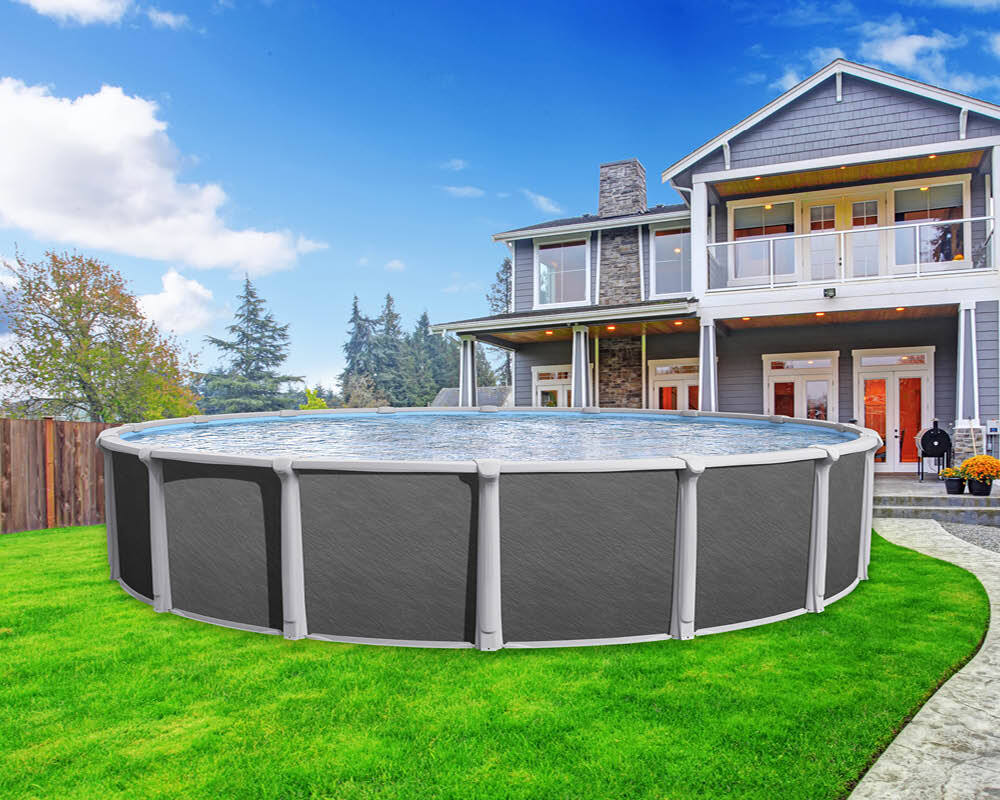

These coatings can be applied to properly finished gunite and formed concrete pools. The finish is tile-like at a much lower cost. Also, it can be used to finish vinyl pools where polymer panels are used. Glass flake coatings can be easier to use than vinyl with no sizing, fitting, or cutting required, which means the installation can be performed faster. The service life in vinyl pools is exceptional, and the product conforms to any shape and size.

The use of insulated concrete forms (ICF) is gaining in popularity as it is less expensive than gunite and conventional concrete forming systems. Micro-glass coatings can also be used on these pool installation systems. In fact, builders/installers can save a significant amount of time and material on large projects like waterparks when using a micro-glass/ICF combination.